Standard Feature

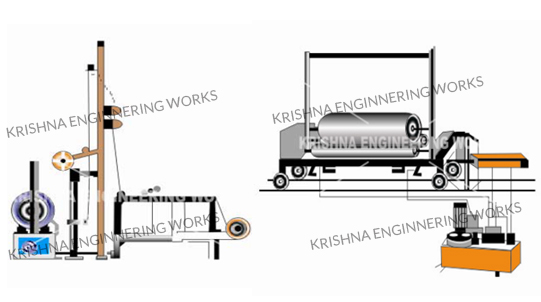

Liner Rewinder Machine

Liner Rewinder Machine Manufacturer for Tire Cord industry, Liner Surface Rewinder Machine, Liner Rewinder Machine is used for any winding & unwinding application for guiding the web to reduce the wastage of the material & to get high production output with minimum man power.

- Let off unit.

- Inspection table with pressure roll device.

- Web centering device.

- Two roll surface polling machine with pneumatic pressing device.

Technical Specification

- Liner Fabric Rewinding Machine

- Completely fabricated from Heavy Duty Chanel Angle structure of Rewinder Stand and Let-Off Stand

- Complete with pneumatic brake and Safety Chucks (Locking Assembly) on Let-Off Station

- Inspection Table covered with S.S. Sheet structure-Guider Roller and Light System for Inspection Fabrics

- The platform, Hydraulic Web Aligner (Power Pack) Unit complete with Hydraulic Cylinder, Air Sensor, Adjuster, Square Pipe, Air & Oil Pipe

- Banana Roller to remove the wrinkle

- Rewinder Unit completely manufactured from Heavy Duty Channel Angle and Angle with Pneumatic Cylinder for lifting the Drum Roller

- Necessary Guide Rollers

- 10 HP AC Electric Motor with Synchronized reduction Gear Box

- Electrical Control Panel Drive with Chain Wheel

- Pressure Rubber Roller

- Pneumatic Panel Board for Control of Pneumatic System

- Necessary Safety Covers